Multi-Scale Multi-Physics Simulations

BE specialises in the design and application of multi-scale and multi-physics geotechnical numerical simulations. Our goal is to run physics based simulations of rock mass deformation based on uncompromised mechanical and physical principles. A key part of this goal is to achieve similitude, i.e. you’ll match the simulation results to the real, day-to-day observations and measurements from your mine or project site.

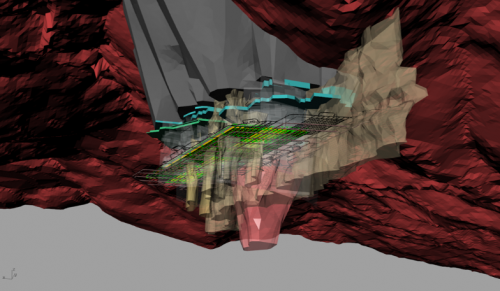

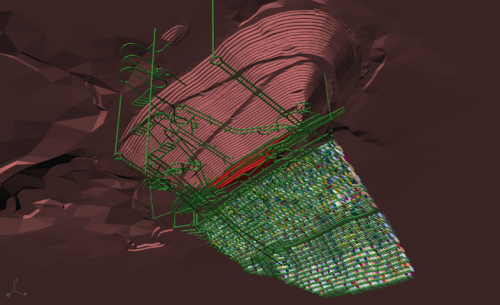

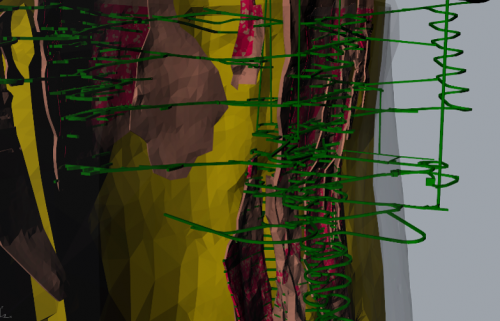

Our multi-scale numerical simulations forecast the mechanical behaviour of rock at all relevant length scales supported by the available structural data. This will be from regional scale down to sub-tunnel scale.These simulations are constructed to have detail at a scale appropriate to the resolution for the investigation being carried out.

The application of a multi-physics simulation framework is the use of an interdisciplinary approach: This approach takes advantage of techniques used in civil engineering, structural engineering, aerospace engineering, hydrogeology, damage and fracture mechanics and allows to capture the interconnectivity of different physical phenomena, hence less assumptions are made and one integrated answer is provided instead of a puzzle of single solutions.

Modell features

Combining both multi-scale and multi-physics techniques is computationally difficult and demanding. BE pioneered the application of multi-scale, multi-physics simulations in the discipline of mining. BE continue to specialize in the design and application of these simulations. To continue to efficiently deliver the robust and realistic geotechnical models our clients have become accustomed to, BE utilises industry leading Finite Element Method (FEM) software suites and in-house developed numerical frameworks.

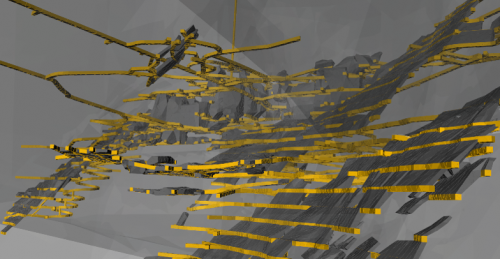

BEs FEM simulations have industry leading detail and resolution. This is due to the use of tetrahedral meshing and years of experience in building complex meshes. The unmatched resolution and detail of BEs simulations allows the modelling of realistic responses for excavations even in large mine scale models.

BEs numerical framework offers a large number of constitutive models. All FEM applications features a plug in architecture for functional extensions, i.e. new constitutive models or other enrichments can be easily implemented and applied.

The robustness and efficiency of a FEM continuum code is combined with the ability to simulate a large numbers of discontinuities, explicitly built using contact or cohesive finite elements. The maximum number of structures in a model is only limited by the available computational capacity to run the simulation. This allows BE to make full use of your geological mapping and structural data sets.

The full parallelization of the algorithms in BE simulations allow for an easy increase in computational performance resulting in shorter turn-around times for model results or higher resolution models at the same cost. You have full flexibility to implement and run the model that is adequate for your situation.

The application of calibration and validation procedures for all of BEs simulations allow a well sounded verification of results based on your field data and on-site-experience. The benefit for our clients are results that answer their specific questions in detail and at a resolution that represent the underlying mechanisms.

If you have any questions or require further information about multi-physics mine-scale modelling projects please contact us or browse our service pages for an overview of our work.