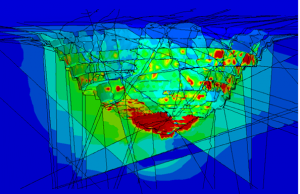

Cut-away section through an open pit showing modelled displacement magnitudes. This model included many faults as shown, as well as pore water pressure effects. The controlling influence of structure is clear, and correlates well with the magnitude and location of movements measured in the pit.

There is a trend for open pits to be mined to greater depths than before. The greater depths are leading to higher underlying strains in the slope and failures arising from rock mass instability have become more prominent. These failures include instabilities resulting from the combined effects of induced slope damage and structure, as well as structurally controlled failures.

Mine-scale, discontinuum numerical modelling has been shown to provide reliable forecasts of open pit behaviour under diverse geotechnical conditions. To be effective, models should include structure, water, detailed three-dimensional geometry and a realistic material model, which are the main controls on pit stability, as every geotechnical engineer understands.

New modeling frameworks have been developed that better capture the interaction between all of these controls on stability: rock, structure and water. We call this approach “high similitude modelling”, and it includes:

- Detailed three-dimensional geometry, including as-built pit shells, future designs, topography and schedules.

- Explicit structures, such as faults, shears, weak contacts and altered dykes.

- Time effects where data allows

- Realistic material models for the rock and structures including strain-softening (cumulative damage) and dilatant behaviour.

- Inclusion of pore water pressure and groundwater percolation effects as well as flow on faults.

- Direct calibration against field measurements of block and underlying slope movements, for model validation and calibration

- Quantified reliability and certainty.

In many mines around the world, realistic stability behavior has been shown to emerge naturally in the high similitude models, allowing reliable forecasts of pit behaviour, identification of geotechnical vulnerabilities and quantitative, field verification and calibration.

Over the past 15 years, Beck Engineering has assisted some of the most complex open pit mines. We regularly assist mines understand complex interactions with geology, infrastructure and underground operations.

Through Simulation Aided Engineering, we are able to review the mine‘s past performance and forecast its response to the proposed schedule through a detailed calibration process.

Speak to one of our engineers about incorporating Simulation Aided Engineering at your open pit mine.

BE specialises in:

- Discontinuum, full 3D scale models for open pits

- Coupled hydromechanical simulation

- Simulation of interactions between open pits and underground operations

- Direct calibration: modelled movements vs measured movements

- Rapid SAE (Simulation Aided Design) for open pits

For more information please contact Dr David Beck.