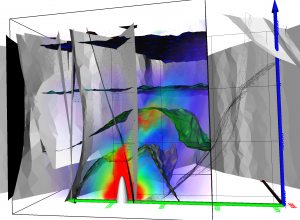

Stress-strain response of a simulated rock mass specimen (8m diameter) at varying levels of confinement. The yield state of discontinuities and the deformation of the specimen at milestones of yield are shown.

Homogenisation & Discrete Fracture Networks

BE has conducted extensive research in the area of rock property estimation, rock strength scaling and homogenisation.

One technique applied for these tasks is numerical homogenisation. This involves constructing a model of the rock mass using a discrete fracture network. The load-deformation response of the ‘synthetic’ specimen can be tested under static and dynamic loading conditions in order to investigate the complete stress strain response of the rock at different length scales.

BE has conducted unique and detailed investigations into rock breakage and fragmentation.

The purpose of the work was initially to better quantify the fragmentation that occurs during cave initiation and propagation, but the research has yielded some interesting results for the detailed analysis of seismicity, ground support and the homogenisation of material properties.

High Similitude Modelling Techniques

Mine-scale, discontinuum numerical modelling has been shown to provide reliable forecasts of open pit behaviour and performance of underground mining under diverse geotechnical conditions. To be effective, models should include realistic stress conditions, structure, water, detailed three-dimensional geometry and a realistic material model, which are the main controls for the geotechnical problem, as every geotechnical engineer understands.

BE continues to improve and develop numerical frameworks that better capture the interaction between all of these controls on stability: rock, stress, structure and water. We call this approach “high similitude modelling”, and it includes:

- Detailed three-dimensional geometry, including as-built pit shells and excavation geometry, future designs, topography, material domains and schedules.

- Explicit structures, such as faults, shears, weak contacts and altered dykes.

- Time effects where data allows.

- Realistic material models for the rock and structures including strain-softening (cumulative damage) and dilatant behaviour.

- Inclusion of pore water pressure and groundwater percolation effects as well as flow on faults.

- Realistic assumption on local and regional stress field conditions.

- Direct calibration against field measurements of block and underlying slope movements, for model validation and calibration.

- Quantified reliability and certainty.

In many mines around the world, realistic stability behavior has been shown to emerge naturally in the high similitude models, allowing reliable forecasts of rock mass behaviour, identification of geotechnical vulnerabilities and quantitative, field verification and calibration.

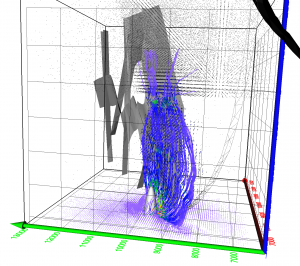

Numerical simulation of fluid migration driven by fluid exsolution from cooling magma chambers

Cutaway view of Relative Fluid Velocity (Vectors), Rock Mass Damage (Volume rendering) and Pore pressure isosurfaces.

This project was undertaken to simulate conditions for potential orebody formation using a hydromechanically coupled, discontinuum, strain softening dilatant model. The study is conceptual: it was designed to quickly define the bracket conditions for formation of orebody like zones in a very specific range of conditions. The end state was to demonstrate the capacity to simulate the mechanics of formation of orebody like conditions in 3d at a large scale. We used a known highly mineralised province as a donor for the fault model, but scaled and mirrored the geometry to protect the anonymity of the site.

The mechanism of orebody formation we have simulated was fluid migration driven by exsolution from cooling magma chambers. The model simulates flow, stress, induced damage and changes to hydrological properties induced by rock mass damage, but does not simulate the chemical processes of deposition. The mechanical and flow conditions are used to interpret pre-conditions for deposition assuming favourable chemistry.

The result of the simulations is that we could generate orebody like confluences of high flow and changes in porosity and rock damage, for scenarios of stress and hydrological conditions that intuitively match the most likely conditions for formation. Significant indicators for deposition are absent in scenarios where intuition suggests orebody formation is unlikely.

Streamlines showing path and velocity. Flow traverses rock mass to major fault, but does not substantially infiltrate additional major or intermediate faults.

Importantly, the shape and extent of the high flow/high damage zones is in some cases qualitatively similar to the different mineralised zones at the donor site.

The analysis points to opportunities for more detailed studies of specific environments and regions, and opportunities for analyzing much large scale processes.

We have not investigated the increments of damage or increments of flow to more precisely review the stages of evolution of each of the highly prospective zones in the model, nor have we looked at indicators of earthquake potential, though it is clear certain events occur in a manner which we have shown is related to event potential in other contexts.

Probabilistic forecasting of mine seismicity

Aside from practical mine engineering and design, several specialist technical tools will be required to engineer and validate new approaches to mining at great depth. Augmenting field measurements and trials, these quantitative tools are key enablers of the simulation aided engineering process for mining methods at great depth.

The current state of development is as follows:

- Strain softening, discontinuum, dilatant LR2 Finite Element models are used to develop correlations between modelled Dissipated Plastic Energy (DPE), the instantaneous peak rate of energy release from a volume of rock (RER) and measured event occurrence (event rate/volume/time). The forecasts are provided as an estimate of relative seismic potential in 3d across time in uncalibrated models, or as an expected probability of events in calibrated analysis.

- Seismic mechanisms in LR2 models show a good match between modelled mechanisms and measured seismic moment tensors—in LR2 models, seismicity is interpreted directly using the energy released as the rock mass degrades. This allows more detailed interpretation of the models, as well as improved utilisation of seismic system data for calibration because like is compared to like. From mining to oil and gas, the combination of the LR2 modelling and moment tensor analysis provides unprecedented understanding of rock mass failure mechanisms: measured and modelled.

- The correlation between RER and measured seismicity can be computed for faults as well as for the rock mass.

- Passive tomography has been integrated with LR2 FE modelling at several mines to better understand the effects of conditioning and de-stressing efforts, to improve model calibration or to track the development of induced rock mass damage in near real time. Combined with systematic, high similitude modelling, the passive tomography provides a remote, 3d, quantitative measure of changes in the rock mass.

These developments provide real, quantitative tools for the engineering of seismicity. At a growing number of mines, engineers have been able to adapt their designs in early planning stages to reduce seismic risk.

For a more detailed summary about mining and reservoir induced seismicity contact Beck Engineering or download one of our documents here:

- A coupled DFE-Newtonian Cellular Automata scheme for simulation of cave initiation, propagation and induced seismicity

- Numerical simulation of the released energy in strain-softening rock materials and its application in estimating seismic hazards in mines

Other Research Topics

Other major research topics are:

- Large-scale 3D modelling frameworks

- Constitutive models and discontinuum models

- Seismic energy

- Hydromechanical modelling

- Oil & Gas models

- Cave modelling

- Mechanics of granular material